The rise of Internet and e-commerce has increased the requirement in customization and personalization to manufacturing. In order to respond the market rapidly, and face a paradigm shift, manufactures shall be capable in high-mix, low-volume production through AI and intelligent manufacturing solutions.

Industrial IoT

Cooperate with industrial IoT partners to assist customers in collecting the production data from various and cross generation equipment, different brands, and diverse protocols. The in-time big data includes the history of whole-processes, which accelerates the strategic decision-making, and applies to further analysis and AI application.

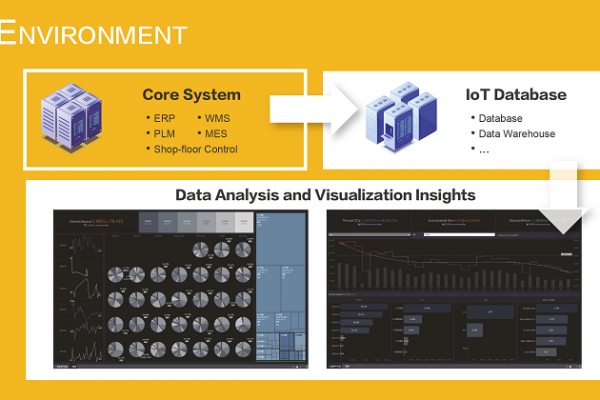

Integration Analysis

Assist customers in integrating big data from each on-site equipment, device, senor to the existing core system or storage. Build a virtual system on the Internet, synchronizing it with the on-site production for instant monitoring and on-site management through big data. Through the visualized business intelligence tools, the managers will identify business insight easier, then accelerate decision-making.

Artificial Intelligence

Assist customers to customize AI models by cloud. Introducing these AI models to the existing system or equipment for optimizing quality, processes, scheduling, and predictive maintenance. Meanwhile, SYSTEX provides an automatic deployment mechanism for retrained AI model to ensure accuracy without disturbing production. On the other hand, SYSTEX also develops subscription-based customer reference solution. Customers can adopt an appropriate one for your specific scenario.